Seems like there is an infinite pile of crow to feast on for the people that mocked Tesla for manufacturing in a tent.

There’s a lot to be said for lithium-iron-phosphate batteries. They don’t have a thermal runaway problem and will survive the “nail test”. Energy density per unit weight is lower, though. Energy density per unit volume is about the same, but the batteries are heavier.

Lower-end electric cars, such as the Tesla low-end models and most of BYD’s output, have already gone to lithium-iron phosphate. Probably a good idea.

If Toyota can manufacture their solid state battery at scale, the energy density will be above that of classic lithium-ion batteries. We’ll see how that next-generation technology works out.

The claim for the solid state battery is that charge times will be around 10 minutes. That’s interesting. A charging station starts to look less like a parking lot and more like a gas station. Two islands with four chargers each can charge eight cars. Charging stations may be able to replace gas stations on the same real estate. Throughput is lower, but not that much lower.

Current standards for electric vehicle charging stations have the following maximum power delivery:

- SAE J1772 DC Level 2 — 400 kW

- IEC 61851-1 — 80 kW

- Tesla NACS — 250 kW

(Again, these are maxima under the standards: many installed charging stations are lower power. A typical Tesla V2 Supercharger provides 120 kW.)

Plans for future higher power charging standards include the Megawatt Charging System (MCS) with a rating of 3.75 megawatts (3000 amperes at 1250 volt DC).

Let’s compare this to a gasoline pump. A typical filling station pump in the developed world delivers around 50 litres per minute (38 l/min in Safetyland), and gasoline has an energy content of around 7500 kcal/litre depending on its formulation (around 5000 kcal/litre for pure ethanol and 8600 for #2 diesel). Plugging these into Units Calculator, we get:

(50 litres/minute) * (7500 kcal / litre) = 26.15 megawatt

so even the proposed MCS (which is primarily intended for large commercial vehicles and buses) delivers only around 1/7 the power of a gasoline pump.

Now, even getting installation of five megawatt electrical service is a pretty big thing in most places (that is the consumption of a very large office building), so it looks like building out an infrastructure which will allow electrical vehicle charging times competitive with gasoline filling will require very substantial upgrades to the power grid and local distribution facilities.

What are the latest facts concerning the impact of rapid charging on battery life? My impression is that it shortens it, but there are frequent changes in battery tech.

Here is an article that discusses charging time vs. battery life.

The main issue with fast charging is that high power delivery into the batteries causes higher heating (because the batteries cannot dissipate the heat of the electrochemical reaction in the battery to the environment quickly enough). Heat causes degradation of batteries, so the more heat, the faster the battery loses capacity. Some electric vehicles have active air or liquid cooling which reduces temperature rise during fast charging, mitigating degradation due to heat. Other vehicles have only passive air cooling, and are more vulnerable.

A 2019 research paper which may provide more detail than most people want is “Lithium-ion battery fast charging: A review” (full text at link). Here is the abstract.

In the recent years, lithium-ion batteries have become the battery technology of choice for portable devices, electric vehicles and grid storage. While increasing numbers of car manufacturers are introducing electrified models into their offering, range anxiety and the length of time required to recharge the batteries are still a common concern. The high currents needed to accelerate the charging process have been known to reduce energy efficiency and cause accelerated capacity and power fade. Fast charging is a multiscale problem, therefore insights from atomic to system level are required to understand and improve fast charging performance. The present paper reviews the literature on the physical phenomena that limit battery charging speeds, the degradation mechanisms that commonly result from charging at high currents, and the approaches that have been proposed to address these issues. Special attention is paid to low temperature charging. Alternative fast charging protocols are presented and critically assessed. Safety implications are explored, including the potential influence of fast charging on thermal runaway characteristics. Finally, knowledge gaps are identified and recommendations are made for the direction of future research. The need to develop reliable onboard methods to detect lithium plating and mechanical degradation is highlighted. Robust model-based charging optimisation strategies are identified as key to enabling fast charging in all conditions. Thermal management strategies to both cool batteries during charging and preheat them in cold weather are acknowledged as critical, with a particular focus on techniques capable of achieving high speeds and good temperature homogeneities.

The devil’s in the details, so it’s likely that different battery chemistries will vary in their tolerance to fast charging and temperature-related effects.

Norway is far enough along in this area that actuals are available. McKinsey has a study.

- On-the-go charging costs about 3x - 4x per KWh vs home charging at off-peak hours.

- Profit margins on running public chargers are quite good in Norway.

- McKinsey says Norway has too many small charging stations and not enough big ones.

- “Sound power procurement, trading, and hedging strategy working in tandem with rigorous on-site energy management are central to optimizing power costs.”

It’s very McKinsey. Their model is big charging companies with big stations and their own energy trading operation.

The government of Norway has an official charging strategy. Norway apparently has enough electricity that supply is not a problem, but getting high-current connections to larger charging stations is.

Norway is, of course, an outlier both in its electrical generation and consumption per capita.

Around 95% of electricity generation in Norway is from hydroelectric power, and it is the largest producer of hydroelectric power in Europe. This is the result of a policy which has been in effect since 1892, and 90% of generation capacity is publicly owned.

Norway’s per capita electricity consumption is 24,182 kWh/year, ranking second in the world after Iceland (51,304 kWh/year). This is more than twice the U.S. at 11,267 kWh/year.

With abundant hydropower, electricity is the most common source for home heating and hot water, which has contributed to developing a grid which can support electric vehicle charging.

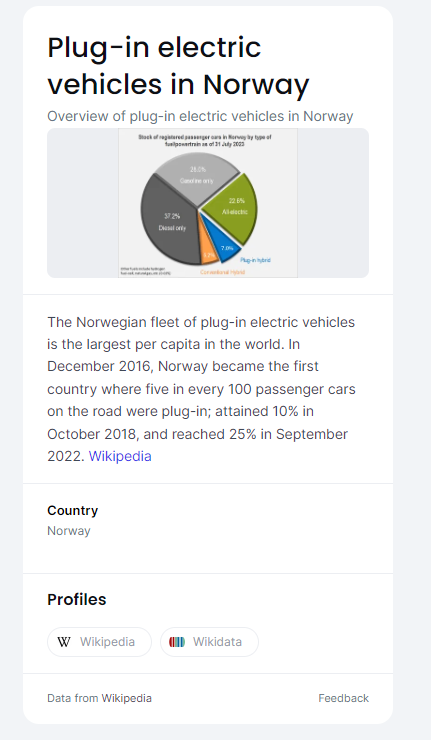

This isn’t to discount the value of the experience in Norway, where around 80% of new vehicle sales are electric, but their circumstances are unusually favourable to electric vehicles compared to countries without abundant base load hydroelectric power.

From Euronews.com:

The number of fully electric cars in Norway exceeded 3 million in 2022, and the share of EVs among the total number of cars rose to 76 per 10,000 in 2021, up from only 2 per 10,000 in 2013.

Although new purchases are 80%, the total percentage of EVs is still very small. Successfully charging less than a percent of the vehicles is not a good indication of how it will go when 80% of the vehicles need to be charged. One car out of 100 can be charged at the bookstore.

Also, just a side note. In the McKinsey report they use EBITA and as Charlie Munger advised. Whenever you see EBITA, substitute BS.

The Euronews link does not lead to that study. But something seems off in the arithmetic. If the share of EVs among total Norwegian cars is (was) 76 per 10,000 – or less than 1% – and the number of EVs in Norway exceeds 3 Million – that implies a total number of vehicles in the order of 300 Million. Not bad for a country with about 5 Million people.

But it can be hard to see the facts through the fog of oil-funded Norwegian hypocrisy.

A good logical check with math. What I did was search for the total number of EVs in Norway and I pulled the number from the summary provided and included the link from which the summary indicated that it got the number.

I just went back that tab and the summary I used indicated some issue. I refreshed the search before I wrote down the issue. On the refresh the summary changed. Previously the link I provided is where the statista.com link is shown in the screen shot below.

The web search also has information from Wikipedia (second screen shot below) that indicated EVs are 25%.

I changed the search slightly to BEV in place of EV, but it did not give me the link.

Sorry for the error and thank you for the correction.

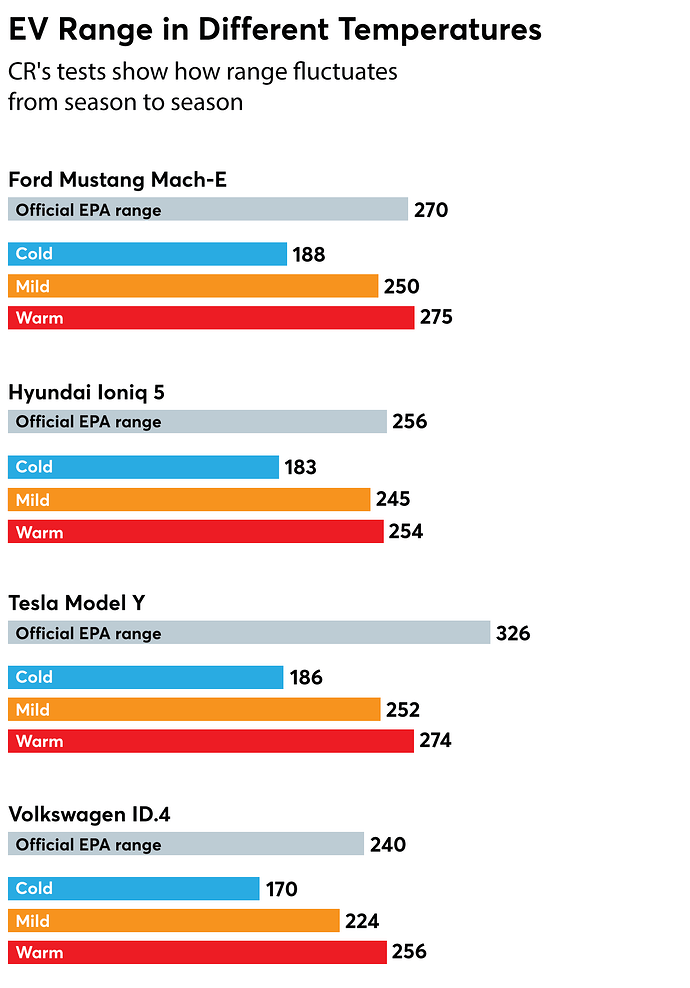

I must wonder as to two practicalities in a place like Norway. According to a brief search, EV batteries lose 12 - 30 % of their range in cold weather - before the heater is turned on. Then, it drops around another 40%. I guess Norwegians just like the “cool” experience of gliding around in green vehicles. Are mink blankets an OEM option I wonder, like the Tsarist Russian troikas?

In 2022, the U.S. magazine Consumer Reports conducted a real-world test of four electric vehicles on the U.S. east coast in February, April, and August.

We began testing in frigid February 2022, repeating the procedure in balmy April and in August heat. Originally, we tested only the trio from Ford, Tesla, and VW in the winter of 2022. We’ve since closed the loop and ran the Hyundai Ioniq 5 on a day that was 17° F (-8 Celsius) on the same route under the same conditions. Like the other three EVs, it followed the familiar trend, showing a remarkably similar 25 percent loss of range compared with the mild weather run.

The EVs were fully charged overnight before each of the runs and were allowed to precondition the cabin to 72° F while still plugged in outdoors. At the same time, we checked and verified the tire pressure. Heated and cooled seats weren’t used.

On the cold day, the temperature averaged 16° F (-8° C), meaning that considerable energy was needed to keep the cabin comfy and the battery pack in its ideal operating condition. The mild spring day was 65° F (18° C) during most of the drive, and the warm summer day was 85° F (29° C) during the drive. Each test day was clear and sunny.

⋮

Some electric vehicles, including current Tesla Model Ys (I don’t know about the one tested in 2022), use a heat pump for heat in winter instead of resistive heating. This heats with less energy from the battery and reduces the impact on range, and also serves as an air conditioner in warm weather. I discussed this in a 2023-08-28 comment on another post.

Chrysler to GM: “Hold my beer!”

Thank goodness we’ve gotten rid of battery pack fires!

… the NHTSA noticed that the “battery thermal event complaint rate now exceeds pre-recall levels.”

They’re “thermal events” now.

Incredible footage - to see the workers jump in and try to put the fire out one moment, then cutting to the burned building shell.

I hope the guys with the fire extinguisher did not get hurt, their courage was admirable.