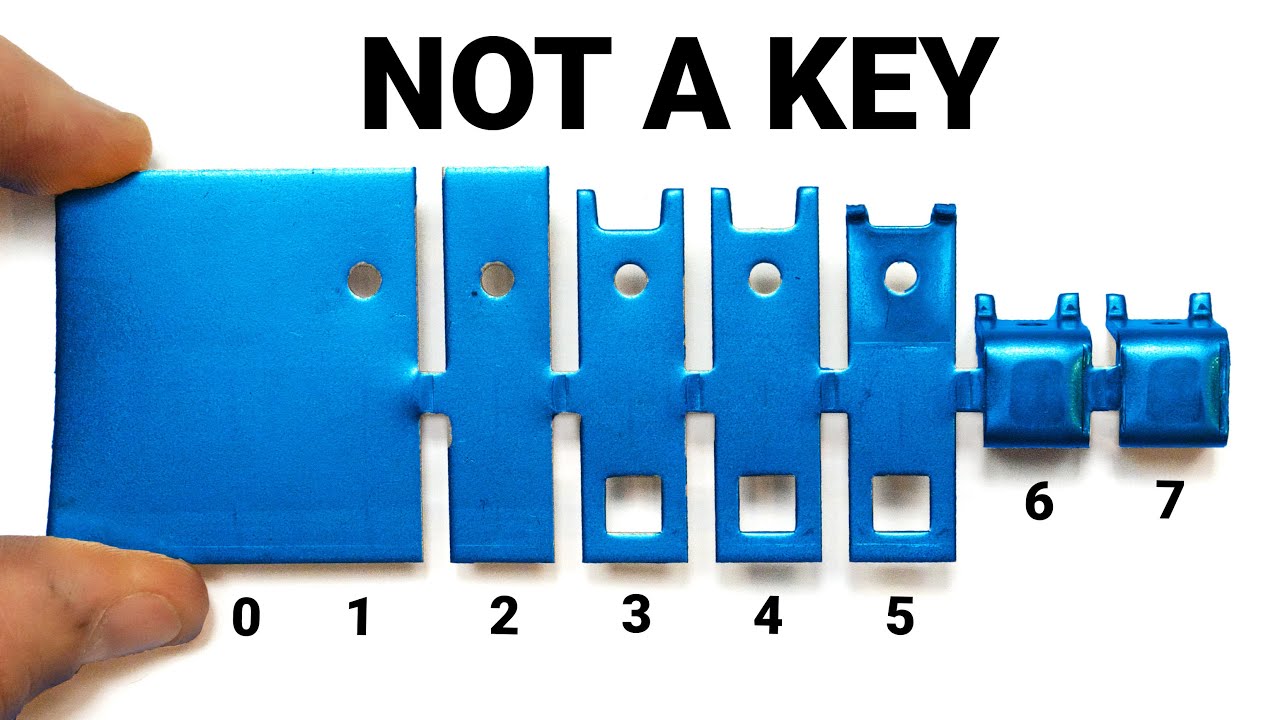

Progressive stamping mass-produces parts from rolls of sheet metal by advancing them through a reciprocating press where with each stroke the part moves from one station to the next on the die, which is configured to perform punching, cutting, and bending operations that form the desired part. The last step shears the completed part from the web that carries it through the press. Scrap is ejected from the press and collected for recycling.

A progressive stamping press can produce parts at a prodigious rate: more than 800 parts per minute, more if the die is arranged to produce parts in parallel from a wide roll of feed metal. One product of the factory shown in the video is blades for kitchen blenders, of which they make between 35 and 40 million per year.