EPA mandate for biodegradable concrete?

Seeing the quantity and distribution of debris, it occurs to me Starship may have dodged several concrete bullets, when it came to just clearing the tower! Based on what we can see, one unlucky concrete chunk trajectory might have made a tangled mess of the entire launch area and all its appurtenances.

Tte factory area, too. Ignoring concrete shrapnel, the shock wave would have done heavy damage to all the flimsy buildings

About halfway into this video there are some pictures of what apparently purports to be the water cooled Steel plate.

Everyday Astronaut and Cosmic Perspective have just released their compilation of video from the Orbital Flight Test. This is in 4K (2160p) video, if your setup can play at that resolution. The tracking sequences were captured at 8K resolution, and show far more information about what was going on than anything I’ve seen before, including very clear imagery of the anomalous plume events during the ascent and the bright yellow flare right when everything started to go wrong. There is imagery from a camera near the launch pad of the approaching cloud of doom and the concrete storm shortly after liftoff. The sound is also superb and captures the crackling of atmospheric clipping due to rarefaction to vacuum by extreme sound pressure levels.

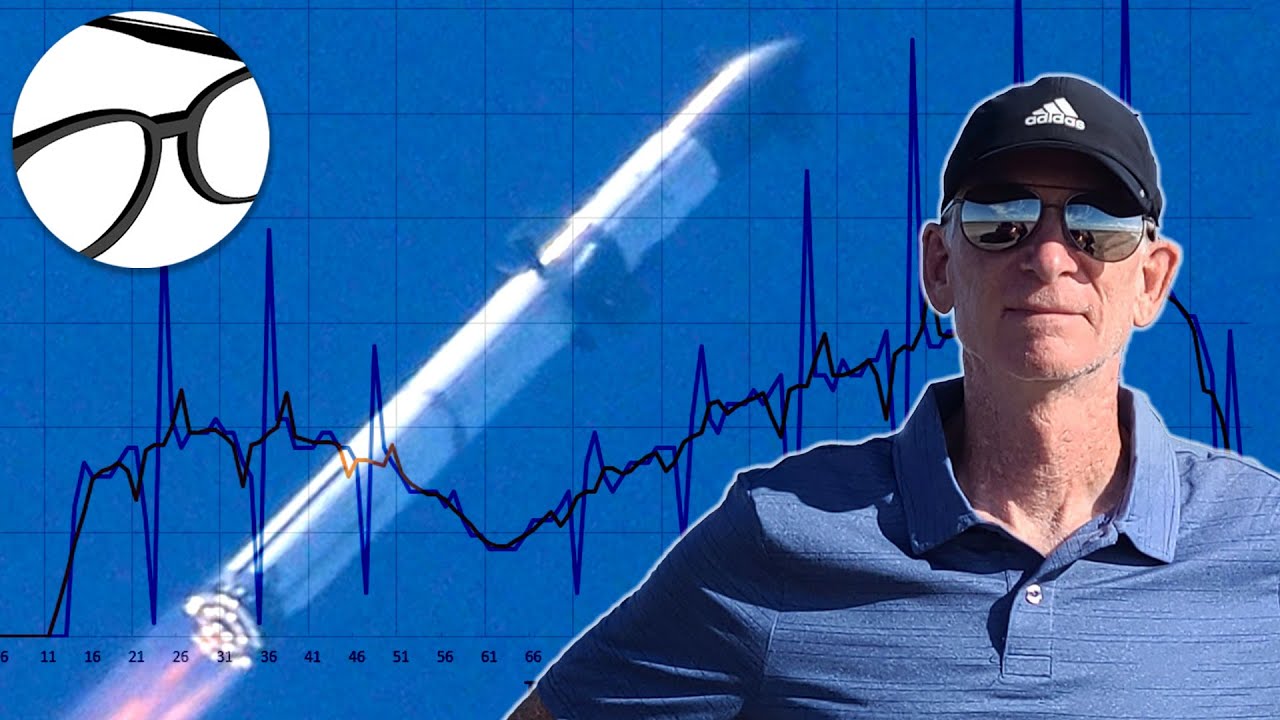

Here is a video from Dr Know-it-all that analyses the flight in detail, plotting the acceleration of the ship throughout the flight from the information shown in the SpaceX telemetry panel and comparing it to that from a Falcon 9 launch. It seems to show that the acceleration was low almost from the start, then dropped off further, and never recovered from what might have been the max-Q “thrust bucket” as is usual for a launch.

This video contains a great deal of speculation, some of which strikes me as off-the-wall (for example, I’ve never heard whether SpaceX differentially throttles the fixed outer engines for steering, nor whether they throttle engines to avoid thrust imbalance after engines shut down), but the acceleration analysis looks correct and, if so, is interesting in understanding what happened.

Seems like it is about as difficult to put together a focused concise video as it is to send a rocket into space.

The analysis (when we get there) seems to tie fairly well to Scott Manley’s observation that losing (say) 3 engines out of 33 has more impact than losing the 10% of engines might suggest. Presumably this is because much of the thrust from the remaining (say) 30 engines is in effect being used to offset the pull of gravity. The “net” thrust available for accelerating the vehicle thus suffers a larger degredation.

That brings us back to the speculation about why some of the engines were out. Did they fail to ignite? Or were they damaged by the Stage 0 flying debris during startup?

There hasn’t been any statement by SpaceX as to when the first three engines failed, and no video that shows the engines from below before the point at which SpaceX put up the status panel that showed them already out. Among those speculating, including me, the general consensus is that SpaceX would not have committed the ship to flight with any engines out, so it is more probable, especially how slowly the booster climbed from the pad and the fact that large chunks of debris were visible flying into the air around half the height of the entire stack, that debris struck the engines after launch commit and before the booster rose out of the zone of flying debris.

Another question is whether the engines that failed subsequently did so for other reasons or were also damaged by debris and simply took longer to fail than the first three. For example, a smaller piece of debris that punctured the regenerative cooling channels in the exhaust nozzle of an engine might cause an overheating problem which would take some time before the heat damage progressed to trigger an engine shutdown.

Given the repeated ‘gee whiz’ nature of Space X’s rocketry, what we already know of this failure of the relatively mundane launch platform and environs - the down-to-earth components of rocket science stuff - is quite surprising. If this turns out to be the root cause of the failure, I hope to hear a candid Musk explanation. I can’t imagine how this wasn’t foreseen.

It has been a worry and under discussion for some time. Here is Elon Musk in October, 2020.

This is his reaction after the launch.

The static test was conducted at 50% of full thrust and the damage was considered to be erosion and acceptable. This launch used (based on numerous reports, but nothing I’ve seen directly from SpaceX) 70% thrust, and the assumption was that damage would be acceptable. They were wrong.

Today’s (2023-04-27) post, “NASA’s Crawler-Transporters”, discusses the massive civil engineering project NASA had to undertake to build launch pads with flame diverters and trenches at a location in Florida where the water table was right beneath the surface. The situation at Boca Chica is almost certainly about the same, and SpaceX gambled they could avoid the massive pyramid-building-scale project with “FONDAG” (calcium aluminate refractory cement) and, later, a water-cooled steel plate.

This may have been an expensive misjudgment, and may cost much more time than iterating changes in the rocket. I’m sure they’re looking at lots of alternatives, especially since they now have large sunk costs in a launch facility in Florida which also assumes no need for a flame trench.

Are the hold downs locked until the thrust reaches 70%?

To my knowledge, nobody knows. There was one description of the launch sequence that implied that the hold-down clamps were released at engine ignition and the ship took off as soon as thrust was greater than its weight (which, as I understand it, is how Soyuz works), but I have never heard confirmation of this from any other source. It seems an odd way of doing business, since you’d usually want to be able to confirm you have all engines at full thrust before committing to flight. Falcon 9, for example, has had several cutoffs after engine ignition when engine monitoring saw something it didn’t like.

If so, there was no abort possibility if, for example, they discovered that the pad experiences excessive failure at 62%.

The acoustic shockwaves were visible in the first of the slow motion replays.

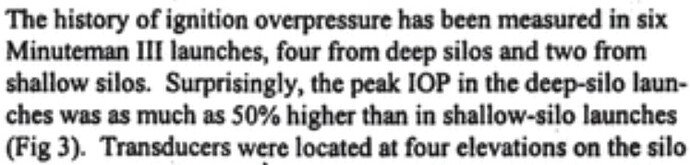

It’s entirely possible that those shockwaves, alone, were enough to cause some engine failures. That means (according to the conventional wisdom about shock dissipation) a “water cooled steel plate” of the kind shown in this video had better be able to disperse water droplets far enough above the plate to have the dissipative effect.

PS: I found this rather paradoxical result after looking up the extreme acoustic environment of missile silo launch:

Mundane stuff – there is a fascinating section in Eric Berger’s book “Liftoff” about the early days of SpaceX. The first Falcon 1 rocket launch failed in 2006. The cause was quickly traced back to “… the failure of an aluminum B-nut on the fuel pump inlet pressure transducer due to inter-granular corrosion cracking”.

That nut cost about $5 – a kingdom lost for want of a horse-shoe nail. The rocket had been exposed to corrosive sea salt spray while being prepared for launch from Kwajalein Atoll.

“They had debated whether to go with aluminum or stainless steel. … Ultimately, Musk greenlighted the use of aluminum B-nuts, because they weigh one-third as much as steel. With rockets, every ounce matters”.

Engineering is always a matter of trade-offs. And bitter experience has often been the main way by which industries have learned which trade-offs are acceptable.

I meant this only in a relative sense, compared to the internal workings of the ship, itself. In professional negligence law, some of the decisions which turn out to be wrong are called “errors in judgment”. They are not negligence, provided the possibilities which turn out to have come to fruition were weighed and decided to be reasonable risks. Negligence would mean not having considered them at all. I imagine that is similar in engineering, so this will likely turn out to be an error of judgment, like the aluminum nut.

I am not sure if “error” is the best word – although we all have to accept that the law uses language in ways that have little connection with reality. The “error of judgment” is only apparent after the item has failed. Prior to that failure, it was simply the best engineering compromise that could be made with the information then available.

The underlying issue is that the only way to test certain concepts is to build them. The Tay Rail Bridge was cutting-edge engineering when it was built … and then collapsed in an unusually powerful storm in 1879. All subsequent bridges were better because of that painful learning lesson. The history of rocket launches is the same – a lot of spectacular failures leading to today’s highly successful launch industry.

With better information, we can make better engineering decisions. That does not mean the earlier decisions were “errors”. It is unfortunate that, in the real world, the only way to get that better information when working at the limits of prior experience sometimes involves pushing the envelope to the point of failure.

Study it forever and you’ll still wonder. Fly it once and you’ll know.

— Henry Spencer