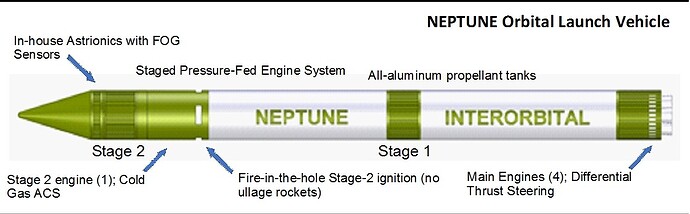

On 2023-06-09, Randa Milliron, co-founder and CEO since 1995 of Interorbital Systems, visited the Foresight Institute Space group to discuss “Achieving Breakthrough Ultra-Low-Cost Space Launch Technology through the Radical Simplification of Systems”. Interorbital’s NEPTUNE launch vehicle takes the “what you don’t have can’t break” design philosophy to an extreme.

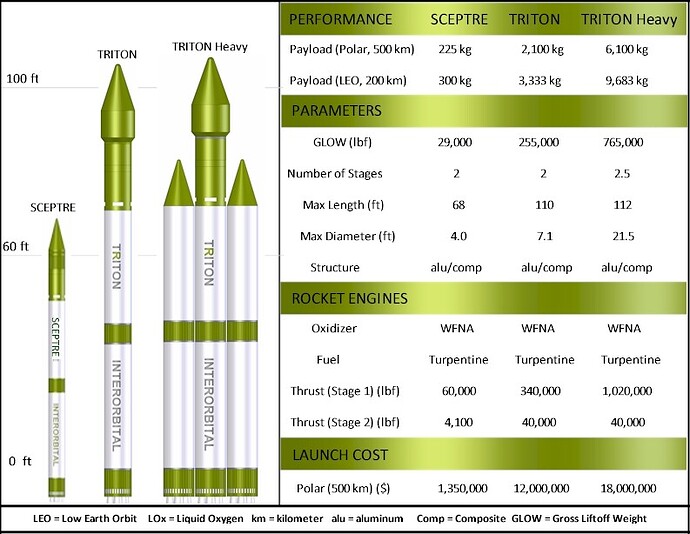

Propellants are white fuming nitric acid (which, despite the scary name, is relatively benign if handled with a modicum of care and can be cleaned up in case of a spill by dilution with water, which turns it into fertiliser) and turpentine, which is made from plant sap. Both fuel and oxidiser are storable at ambient temperature and pressure and are dense, providing a high density specific impulse. Engines are pressure-fed, eliminating complicated and heavy pump mechanisms and intricate start sequences. Engine combustion chambers are nozzles are ablatively cooled, eliminating expensive-to-manufacture and failure-prone regenerative cooling systems and their “plumber’s nightmare” complexity. First stage thrust vector control is by differential thrust of the four engines, eliminating engine gimbal hardware and actuators, along with flexible propellant lines. The second stage engine is also fixed, with cold gas thrusters used for three axis attitude control. The second stage is ignited before the first stage has shut down (“fire in the hole” staging), eliminating ullage rockets to settle propellants in the tanks. Larger launchers are assembled by horizontal stacking of modular propulsion units, providing commonality and economy of scale in engine and structure manufacturing.

Here is a montage of manfacturing, engine, and flight tests.