Earlier posts in the series explored the original 8 inch floppy disc (or diskette) technology and repaired some vintage drives.

- The Curious World of the 8 Inch Floppy Disc

- Repairing a Vintage 8 Inch Floppy Disc Drive

- Fixing More 8 Inch Floppy Drives—The Many Forms of Failure

- Recovering Data from Obscure 8 Inch Floppy Disc Formats

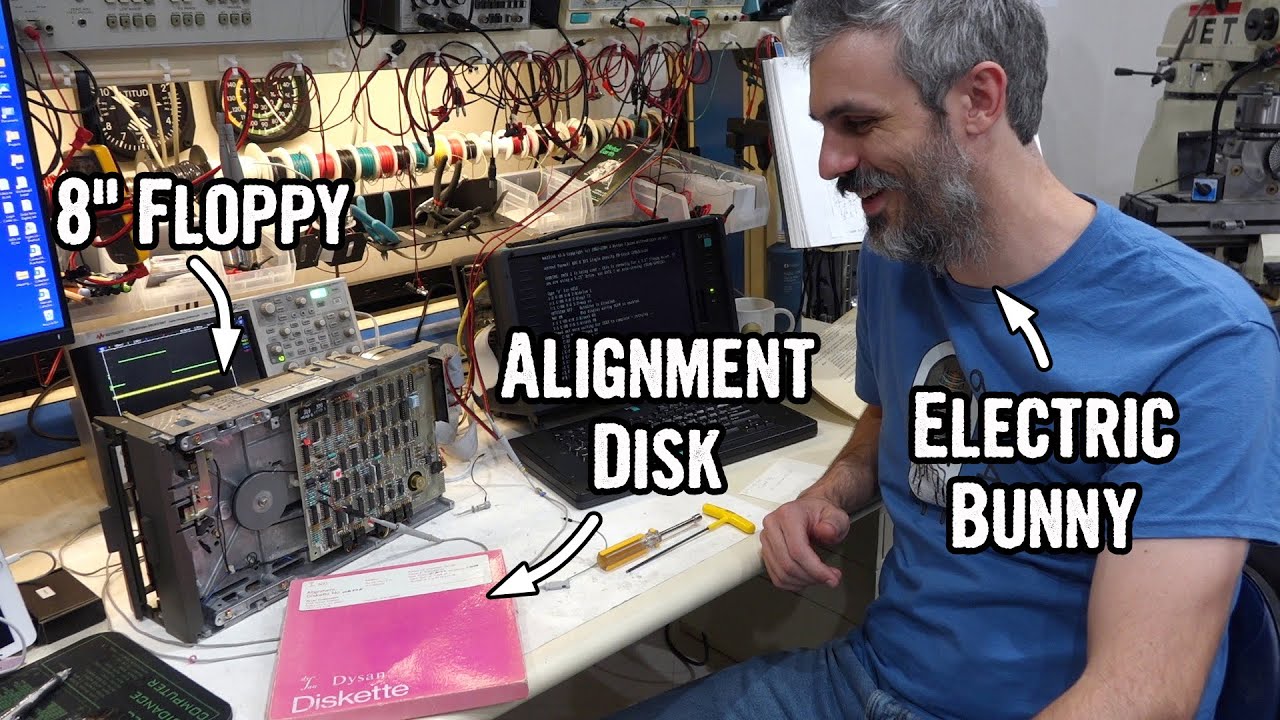

One of the ways floppy disc drives reduced cost was to use purely mechanical positioning of the head over the data tracks on the drive. While most hard disc units employ some form of servo control to centre the head over the track, media interchangeability among floppy drives requires the head positioning mechanism to be precision (well, precise enough for a floppy) calibrated to align with the specified radius of each track. This means that every time the drive is disassembled or the positioning mechanism is repaired, it must be re-aligned. This is best done using a pre-recorded calibration diskette from the manufacturer (which can be difficult to find these days), but can be accomplished if necessary with a data disc recorded on a known-good drive.